In the golden autumn season, the fields of northern China are ablaze with gold, the joy of harvest surging with the ripples of wheat. The nationwide autumn grain purchase has begun, and the curtain is quietly rising on the "north-to-south grain transport."

From the golden waves of wheat on the Northeast Plain to the bustling ports of South China, the "southward journey" of a single grain of grain traverses mountains and rivers, stretching over 3,500 kilometers, connecting the hard work of countless people and impacting the warm daily meals on people's tables.

Today, let's follow a grain of rice and see what "hardcore equipment" independently developed by the UGOOD Group silently safeguards its journey.

First stop: Northern fields. Drying and assembly, efficient transport. The journey begins in the vast northern fields.

After harvesting, the grain has a high moisture content, which is where the grain dryer comes in. Through stable hot air circulation, it quickly reduces the moisture content of the grain, effectively preventing mold and preparing it for long-distance transportation and long-term storage.

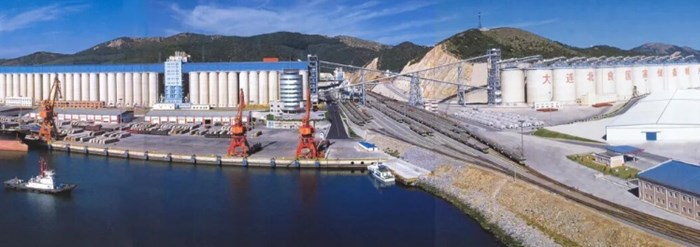

After drying, the grain is transported efficiently via multimodal transport, including road and rail, to major coastal ports in northern China. As key nodes in the north-to-south grain transport system, northern port hubs such as Dalian Beiliang Port, Yingkou Port, Jinzhou Port, and Dandong Port are operating day and night at high efficiency. Giant ship loaders continuously load grain from the vast fertile lands of Heilongjiang, Jilin, and Liaoning provinces into bulk grain ships.

Thus, the journey of grain across the sea to the south officially begins.

Second Stop: Southern Hub

Intelligent Unloading, Efficient Diversion

After several days at sea, the bulk grain ship slowly berthed at the Nansha Port grain terminal in Guangzhou. Here, a "hardcore operation" showcasing modern logistics efficiency began to unfold. Behind this is a complete set of advanced logistics systems and innovative equipment planned by the UGOOD Group: multi-point unloading conveyor belts, which can flexibly select multiple unloading points on a fixed route, working seamlessly with low-breakage self-cleaning bucket elevators, making grain transportation as precise and convenient as "ordering food."

The low-breakage self-cleaning bucket elevator effectively reduces breakage during grain lifting:

The reversible crushing device installed inside the silo can extend and control the grain's falling path through a series of cleverly designed chutes, significantly reducing the breakage rate.

After a brief stop at the port warehouse, the grain will embark on its next transfer according to the shipper's transportation arrangements. At this point, the efficient unloading system begins operation:

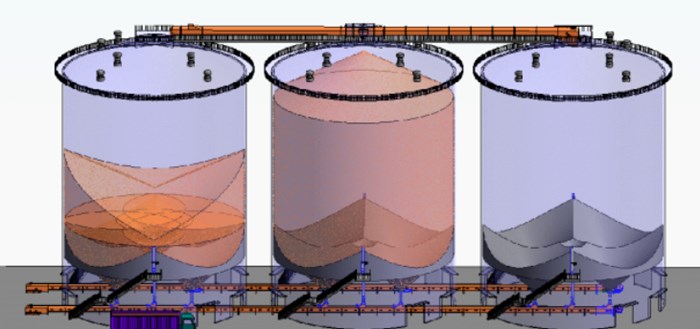

The four-cone shallow circular silos and the conveyor belts beneath them work in tandem, allowing a single silo to unload over 2,000 tons per hour, ensuring a smooth and efficient grain turnover.

Four-cone bucket large-diameter silos, fully automatic unloading:

The side-wall dust-suppressing hoppers quickly and accurately deliver grain into the truck beds below, effectively controlling dust emissions. This improves efficiency while ensuring a clean and environmentally friendly grain depot environment.

Behind the highly efficient warehouse entry and exit operations lies a powerful "smart brain" overseeing the entire process—a fully automated control system providing precise scheduling. Take ship unloading operations as an example. In the past, entering and exiting warehouses required multiple people working together; now, only two staff members can remotely control the process from the control room. This system not only improves the overall port operation efficiency by 20%, but also enables real-time linkage and intelligent scheduling with rear railway and road freight information.

Third Stop: Regional Grain Depot

Unblocking the Last-Mile "Micro-Circulation"

Starting from the dock, a portion of the grain is transported by road to the Guangzhou Huangpu District National Grain Depot, a crucial node for ensuring emergency grain supply to the Guangdong-Hong Kong-Macao Greater Bay Area.

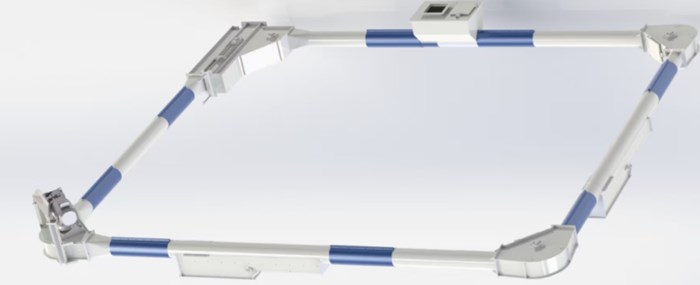

Here, the high-capacity circulating tubular chain conveyor demonstrates its powerful multi-scenario application capabilities. Innovatively applied to the depot's new multi-story warehouses, it solves the problems of traditional equipment's single function, low output, and short conveying distance, making the flow of grain between warehouses and trucks incredibly smooth, truly breaking through the long-standing "last mile" bottleneck in the grain transportation system.

High-capacity circulating tubular chain conveyors can flexibly shuttle between various types of warehouses:

Guangzhou Huangpu District Grain Depot Building Warehouse:

In the past, it took manual labor to move a conveyor belt to remove tens of tons of grain from the warehouse. Now, with the one-click operation of the tube chain conveyor, the efficiency of removing grain from the warehouse has been greatly increased from 50 tons per hour to 300 tons per hour.

Fourth Stop: Broad Terminals

Precise Processing, Reaching the Table

Besides ensuring local supply in Guangzhou, these grains will continue their journey to a wider market.

Some are efficiently and cleanly loaded into standard containers at container loading stations and transported to the southwest via rail ("bulk-to-container" conversion), or delivered to end consumers by road; others are transported upstream along the Pearl River to inland ports along the river.

When the grain arrives at the processing plant, its "southward journey" enters its final chapter.

Here, a cleaning screen performs meticulous processing on the grain. This equipment acts like a strict "quality inspector," efficiently removing various impurities before processing to ensure the purity and safety of the raw materials.

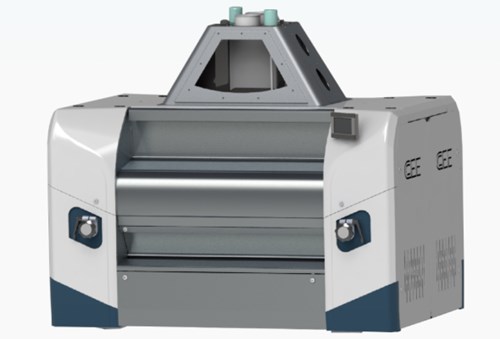

Finally, in the modern processing workshop, the domestically produced intelligent milling machine plays the "final role." It has overcome the "bottleneck" problems in the domestic grain machinery industry, such as automatic milling gap adjustment, sensing and online data monitoring, and efficiently grinds wheat grains into fine flour. It uses technology to protect the last link of grain from grain to powder, so that grain that has traveled thousands of miles can eventually become a warm and delicious meal on the tables of thousands of families.

From north to south, the journey of a single grain of grain is a test of efficiency and the balance between cost and efficiency, and a vivid microcosm of the modernization of China's grain supply chain.

From field dryers to shallow circular silos at docks, from efficient operations at northern grain ports to the intelligent brain of southern hubs, UGOOD Group has continuously cleared bottlenecks, smoothed the flow, and boosted the momentum of the "North-to-South Grain Transport" artery by building a three-pronged development system of "hard infrastructure + soft environment + new technology."

Efficient grain intermodal transport not only effectively reduces logistics costs and improves production efficiency, but also plays an indispensable role in saving grain and reducing losses, serving national strategies!