Working principle:

The refrigerant inside the heat pump drying main unit is used as a medium to continuously vaporize and liquefy in the copper tube. The refrigerant can vaporize at a temperature of dozens of degrees below zero. Due to the temperature difference with the outside world, the refrigerant will absorb the heat energy in the air and vaporize, and then pass through the compressor to become a high-temperature and high-pressure gas, which is released into the drying room through the condenser. After that, the refrigerant will release the pressure through the expansion valve, return to the low-temperature and low-pressure liquefied state, enter the evaporator to absorb the heat energy in the air, and then return to the compressor for the next cycle.

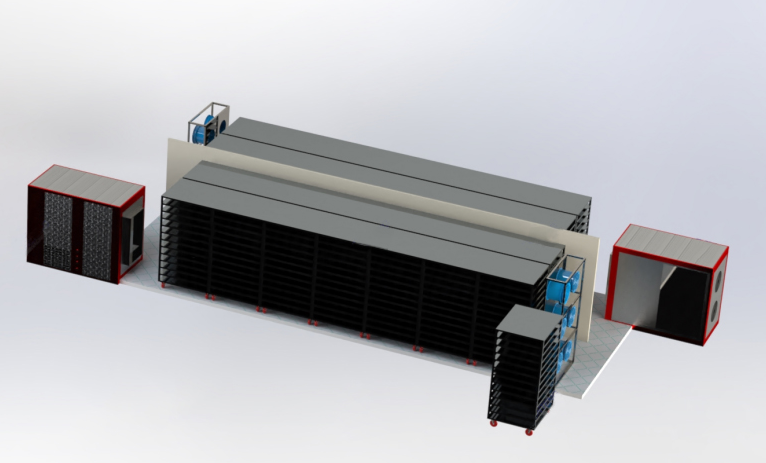

The heat energy is generated through continuous circulation, which heats up the interior of the drying room. After that, under the action of the high-efficiency circulating fan and the high-insulation polyurethane insulation board, the heat utilization rate will reach nearly 100%, ensuring the high efficiency of material drying.

Advantages and characteristics:

1. Wide range of applications, suitable for various agricultural product drying, dehydrated vegetable processing, candied fruit and dried fruit making, Chinese medicinal material drying, scented tea drying, meat and fish drying, grain drying, food processing, paper tube drying, wood drying and other industries.

2. Intelligent processing, the heat pump dryer equipment itself is equipped with an intelligent PLC microcom

puter control system, which can realize the control of temperature, humidity, duration, mode, stage, air volume, dehumidification and other parameters during the material drying process, ensuring that the drying process is always in a reasonable environment, so that the quality of the finished dry goods is guaranteed.

3. High efficiency and energy saving, the air energy heat pump dryer equipment adopts energy-saving technology. Our factory has actually calculated that using 1 kWh of electricity can generate about 3.8 kWh of heat, which saves about 75% of energy consumption compared with traditional drying methods. In addition, the application of polyurethane insulation board room and high-efficiency circulation fan makes the utilization rate of heat energy close to 100%, and the drying is faster.

4. During the entire drying process, the heat pump dryer produces pure hot air, and the interior of the drying room is also a closed environment. Therefore, the entire drying environment will not cause any pollutants to invade the material, and the drying quality is very reliable and trusted by users!

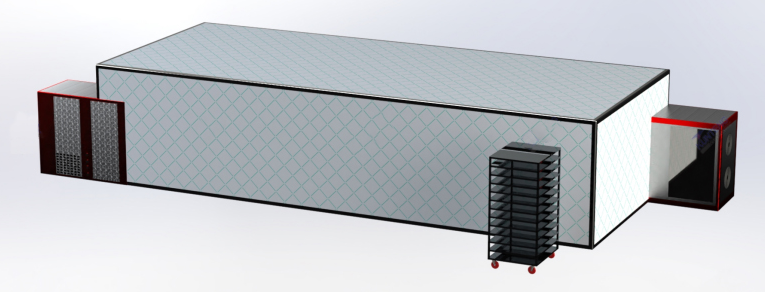

5. Convenient and fast installation, modular combination method, makes the air energy heat pump disc dryer equipment combination more convenient, occupies a small space, and ordinary installation engineers can complete it in about half a day. The overall operation is also very convenient and quick. You can use it directly after simple instructions.

Customized.